Hey, listen… In today’s digital age, cell phones have become indispensable in our lives. From staying connected with loved ones to managing our daily tasks, these pocket-sized devices are our lifelines. However, cell phones are prone to malfunctions and damage like any other electronic device. In this guide, I’ll show how I did the troubleshooting and repair of my cell phone.

WARNING

Tinker with lithium batteries may cause harm to yourself. Pierce the battery body may cause fire or explosion. Proceed at your own risk.

Read the disclaimer here.

The Device

The cell phone was a Motorola Moto G 2014 (model XT1033 – falcon) running custom firmware, the LineageOS 14.

Tools and Materials

For most phone repairs, you’ll need some basic tools such as:

- Philips or Torx screwdrivers

- Spatulas (plastic and sometimes metallic)

- Plastic prying tools (I use cheap guitar picks and custom plastic spatulas)

- Tweezers

- Multimeter (a trusty one)

- Isopropyl alcohol (Isopropanol)

- Soldering iron

- Solder

- Rework station (for SMD components)

- Microscope (a chip USB microscope will do the job)

Additionally, having access to online resources such as repair guides, tutorial videos, and forums can be incredibly helpful principally when opening/disassembling the device.

Identify the Problem

As I said in my other post: Diagnosing and Fixing Faulty Electronics; I started the troubleshooting by trying to identify the problem.

I could not turn this phone on by pressing the power button, and nothing appeared on the screen when the charger was plugged in. Also, I know that someday the phone suddenly stops working. I also know that the phone was not dropped and there was no water damage. At this point, my assumption was some short circuit on any component or maybe some burned integrated circuit.

Disassemble and Diagnose the problem

As the cell phone was completely dead, there was nothing to do aside to take it apart.

Disassembling

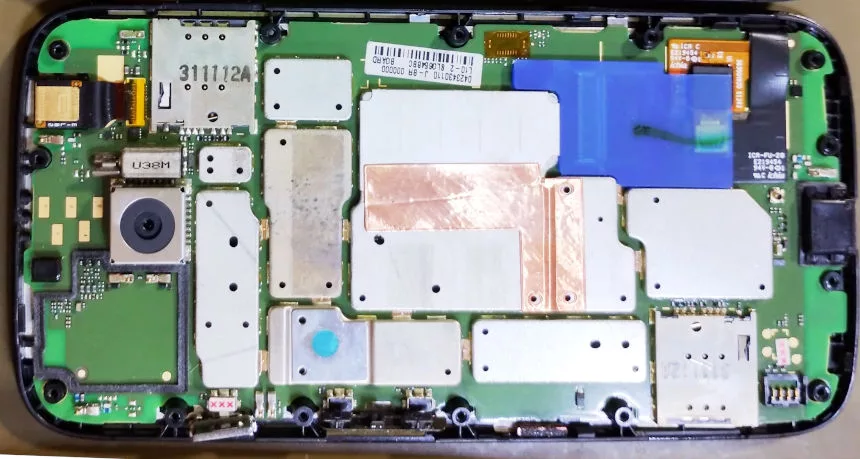

I removed all the back cover with the guitar pick exposing the innermost cover with Torx screws.

You can expose the battery and board after removing all the screws.

I used a plastic spatula and some drops of isopropyl alcohol to remove the battery. The battery is fixed with a two side adhesive tape. You must be careful not to pierce the battery shell and expose the lithium compound. If you do, it may burst on fire.

Always remember to put in a safe place all the pieces and bits that may fall off the opened phone, especially the screws. It is a good idea to cover the camera lenses with some tape to prevent dust deposition while the device is disassembled.

The next step is to provide some voltage and try to power the phone. If the phone turns on, the problem may be the battery. Unfortunately, that was not the case for this phone.

Powering the Phone

To connect the power supply to the phone I used an old battery of the same type as scrap part to build an adapter. I cut the battery connector soldered wires to the circuit trace in the flex cable to make the adapter.

I used the new phone battery to mark the plus and minus sides. After soldering the wires, I applied some hot glue to the solder joints to act as a stress reliever.

Pay attention not to invert the wire polarity. It is a good idea to turn on the power supply before connecting to the phone and set the current limit at 500mA and the voltage between 3.7V and 4.1V. If you do not limit the current and the board is in a short circuit, you can blow up some other component releasing the magic smoke. I wrapped some tape around the connector just in case to prevent any shorts.

Before connecting the power supply, I checked the battery voltage and it was 3.8V which is normal. So, I connected the power supply to the phone using the custom connector, and to the surprise of absolutely nobody, the current was a little too high. Yes, 316mA is too high for a dead phone. Indicating that some circuit component was messed up, taking all this current and surely getting hot.

Sensing the warmth

I started to probe all the cellphone parts with the back of my finger to sense any heat source as I don’t have a thermal camera, yet.

I probed all the parts with my finger for about 3 minutes and I was feeling some warmth coming from the red areas on this picture but after another 3 minutes or so, I found this little capacitor pointed by the red arrow at the bottom of the image, which was mad hot. At this point, I did not doubt that this capacitor was a bad cap.

Removing the Board

We have to extract the circuit board before removing the capacitor with the heat gun. The high heat may damage plastic pieces and the screen behind the board.

This task was not as easy as I expected.

There are three arrows in this picture. All the arrows indicate where you have to unplug flex connectors. Use tweezers when appropriate.

The blue arrow indicates the connector beneath the blue rubber protector.

The red arrow indicates the front camera connector. The camera and the connector were glued on the board with a spongy tape so be careful.

The green arrow shows the location of the touchscreen flex connector (I guess). This is a tricky connector because it is placed at an angle with the screen connector (blue arrow). The red area shows the location where a double side tape was applied to secure in place a “flex board” glued on a metal plate. This part was a pain in the neck to remove. I used a plastic spatula and some drops of isopropyl alcohol to ease the removal. Be careful because you can rip off the flex board from the metal plate. This would be the end of the screen/touch.

After removing all the flex cables and unglueing the flex board (marked with the red area), you can tilt the board from the opposite side of the red area. The board is also glued with a double side tape but is much easier to lift with the help of a plastic spatula.

Fixing the Problem

I removed the bad cap using the heat gun, tweezers and the microscope. This capacitor was tiny. I do not know what this part of the circuit is for but I guess it’s related to the camera or the proximity sensor.

I tested the capacitor with the multimeter after I removed it and sure enough, it was shorted.

This capacitor was part of some filter because it was in parallel with some resistors, so I didn’t bother to replace it.

After that procedure, I pressed the power button and voilà the phone turned on!

Conclusion

Repairing the cell phone by yourself not only saves money but also contributes to a greener planet. By taking matters into your own hands and learning how to troubleshoot and fix common issues, you’re not only extending the lifespan of your device but also reducing electronic waste. Every repaired phone means one less device ending up in a landfill, helping to mitigate the environmental impact of our digital consumption.

See ya!